Table Of Contents

Tilers Place is reader-supported. When you buy through links on this site, I may earn an affiliate commission on qualifying purchases.

BEST HANDHELD TILE SAWS

Complete Guide and Comparison for 2025

Looking for a new wet or dry handheld tile saw?

This full in depth guide is for you, covering all the leading brands and putting them under the microscope.

It’s the only guide you’ll need when buying your next wet or dry handheld tile saw.

Click here to jump to the best handheld tile saws information table

BEST FOR D.I.Y

Ryobi 4″ Tile Saw

Will do anything you’d need it to at half the cost of professional tile saws. Has wet-cutting, adjustable cutting height and miter capability. It’s not built for daily, extensive use so if you’re aiming to use it professionally, go with the Metabo CM4SB2 reviewed below.

BEST FOR CUTTING STONE

Flex CS 40

Affordable but heavy-duty masonry saw equipped with quality water fittings for long term cutting of stone like granite or marble. Handle and guide help for steady cutting. Check out the CS Unitec EDS 181 for a professional solution.

Metabo CM4SB2 – Best Hand-held Tile Saw

The Metabo tile saw is a highly versatile and feature-laden hand-held tile saw at a great price. Its also the most modern tile saw and able to be setup for wet cutting.

I’ve owned numerous in my professional life and recommend it to all tradesman wanting a versatile and heavy-duty 4″ Saw for tile, stone tile and concrete.

Did You Know? There is more than two ways to cut tile with a power tool. A table tile saw and angle grinder are commonly used.

But what if you want a more stable and wet-cutting power tool?

Hand-held Tile Saws! The best tool you never knew about.

I review the best-selling diamond blade handheld tile saws on the market and give insider information on each one. Along with pros and cons I give you links to the best deals available online.

Unlike other reviews you will find online I do not announce the winner solely on the fact it is popular or has a massive brand name.

I will give you proper facts about each wet or dry handheld tile saw and give recommendations on which tile saw is right for you, whether you are a trade professional or a handy DIY-ER keen on home improvement.

By the end of this guide you will know which one to buy and understand a whole lot more that you never knew about handheld tile saws.

Are you ready to cut through the B.S and reveal the real world facts?

I am!

Let’s go!

Handheld Tile Saws – Compare the Best

| Name | Wet Cutting? | Amps | Weight | Max RPM | |

|---|---|---|---|---|---|

| Hitachi CM4SB2 - Best Choice | Yes ✓ | 11.6 (2,090 watts) | 6.2lbs (2.8kg) | 11,500 RPM | Check Price |

| Makita 4101RH | Yes ✓ | 7.9 (1,050 watts) | 6.5lbs (2.9kg) | 13,800 RPM | Check Price |

| DeWalt DWC860W | Yes ✓ | 10.8 (11,88 watts) | 6.6lbs (3.0kg) | 13,000 RPM | Check Price |

| Makita 4100NH | No ✕ | 12 Amps Advertised (9.6 Amps written on Tool) (1,500 watts) | 6.5lbs (2.9kg) | 14,500rpm | Check Price |

The Best Handheld Tile Saws – Quick Links

Eager to get cutting right away?

Here are the links to the best handheld tile saws.

Choose your flavor and go for it.

None of these tile saws will let you down.

Makita 4100NH

• Highest RPM of all the tile saws on review here.

• Cheapest out of all four tile saws.

• Dry cut only

INTRODUCTION TO THE BEST HANDHELD TILE SAWS

Handheld tile saws are a mainstay tool for many professionals thanks to their small size, massive power, capability to cut either wet or dry and unbeatable portability.

For such a compact machine, they offer the same level of cutting power akin to that of a full blown table wet tile saw alongside more stability and versatility over the ever-popular angle grinder.

With various models equipped for either dry or wet cutting, a hand held masonry and tile saw is truly a power tool that is worth investing in. With a quick change of the diamond blade, you are ready to cut any hard masonry surface, from glass tile to bricks and natural stone like marble.

Due to their popularity there is a market flooded with plenty of different models. From the cheap and nasty no brand tile saws best left in the trash to the top of the line professional tools.

The great news is you do not need to spend a fortune to get the best hand held wet tile saw that will last you years, for what they offer you, they are darn cheap and if you look after them, they’ll go for years without any issues.

For the versatility the electric wet tile saw brings you, it is a true bargain and essential bit of kit in the tool box of any one working with masonry, kitchen counters and tiles.

A wet tile saw with a diamond blade is also much quicker to setup and use over a table tile saw and most also provide wet cutting so it’s almost a one stop shop for your cutting requirements.

The Aim Of This Review

My review aims to show the best and worst features of the best selling and most popular diamond blade handheld tile saws available on the market today and rank them on a basis of all rounder versatility.

The winner needs to be reliable, well designed, versatile and suited for daily use for a professional. All while being affordable.

Tough criteria indeed, that is why I selected the most popular wet masonry saws on the market in an aim to find the champion.

They are all professional grade, everyday work horses designed for the toughest of duty cycles, you won’t find any enthusiast saws here.

Whichever one you decide to buy you can be assured it will keep up with whatever you throw at it.

And more.

Let’s begin!

Time to find the best tile saw!

Hello fellow tilers, stone masons and DIYers to my review.

My name is Carl and I have been working professionally as a tiler for the last 25 years.

In all of those many years I have been working with a handheld tile saw with every job requiring a cut or a thousand on this incredibly versatile tool. It’s my go-to electric tile cutter and one of the most essential tiling tools I own.

I hope by the end of this review you will be armed with all the information you require and will be ready to purchase your next handheld tile saw.

Let’s begin!

Ryobi 4″ Tile Saw

Ryobi 4 Inch Quick Specifications:

Motor power: 12 Amps Advertised

Max RPM: 13,700rpm

Weight: 9.4lbs (4.2kg)

Depth Gauge Included: Yes ✓

Diamond Blade Included: Yes ✓

Wet Cutting: Yes ✓

ThisWhen I initially wrote this review, I ignorantly thought that only professionals would read it.

After many comments came through from handy homeowners and other casual users, I realised I completely overlooked an equally important demographic! So this one’s for you lovely people that are out there cutting crazy stuff!

For the occasional user not requiring a professional grade hand held wet saw, the RYOBI 4″ Tile Saw would be my pick.

It offers everything you would ever need in a very affordable package whilst not being dirt cheap and tacky like most entry-level tile saws can be. (I’m looking at you QEP.)

Ryobi has established itself as a medium tier power tool manufacturer that offers quality tools for occasional/DIY use. That means they’ll work great, but are not engineered to survive daily abuse like a trades person would put it through. They come with a 3-Year Limited Warranty for this reason. The limited aspect will most likely say that it’s not made for professional use, hence the “Limited” in the warranty.

If you are looking for a cheap but effective saw to cut things like glass, any type of stone (e.g for bench tops ) or any type of tile, the Ryobi 4″ saw will serve you well. It also comes with wet-cutting ability and a hose in the box!

The main drawbacks of this saw apart from not being built to survive daily abuse is the weight. It’s significantly heavier than any other hand held saw in this review. That’ll be a result of using cheaper metals that are subsequently heavier. Whilst you may not even notice it for the amount of cutting you’ll put it through, it’s important to keep in mind if you’ll be doing long, extended cuts.

I’ve had days where I was using my Metabo CM4SB2 for most of the day and my hand would start giving out on me, so weight of the unit is something I always keep in mind.

If you’re in the market for a hand held saw for occasional use and don’t want to fork out a lot of money, go with RYOBI.

Makita 4100NH – 4th Place

Makita 4100NH Quick Specifications:

Motor power: 12 Amps Advertised (9.6 Amps written on Tool) (1,500 watts)

Max RPM: 14 500rpm

Weight: 6.5lbs (2.9kg)

Depth Gauge Included: Yes

Diamond Blade Included: Yes

Wet Cutting: No.

Pro's

- Highest rpm out of all saws being compared.

- Most affordable saw out of all being compared.

Con's

- One of the heaviest in the group being compared.

- Lack of a water system disqualifies this saw from making any wet cuts natively. In a test for the most versatile masonry tile saw, this is a major let down.

- Lock-Off switch is very annoying for a full days work. It has a clumsy mechanism that does not work fluidly and often times is hard to push in.

Who Is This Saw For?

- Brick Layers

- Casual Users

- DIYers

- Landscapers

- Contractors working with Cement Board

- Tilers requiring an inexpensive back up saw

Makita 4100NH Review

On paper the Makita 4100NH looks to be a great competitor in this review and it certainly has a few points going for it.

Out of the four it has the 3rd lowest amp output motor at 9.6amps but it is biting on the heels of the DeWalt DWC860W at 10.8 amps.

The motor however offers a sensible 13,000 RPM max speed which makes it compatible with most blades, including diamond blades for cutting tiles. 13,000 RPM is about the maximum speed that I would feel comfortable using. Anything higher makes it difficult to find blades as most are rated for 13,300 RPM.

The added rpm will enable you to make quicker cuts over a saw with a lower rpm motor however it is important you remember to check the max rpm rating of the saw diamond blade you attach to the saw.

All diamond blades have a maximum rpm rating they are capable of handling and going over that may lead to the diamond blade being over stressed and causing it to shatter.

A tile saw shattering is like a grenade going off with shrapnel flying everywhere, not even a full face mask can protect you then. So it is imperative you remember this.

The Best Parts I like About The 4100NH

What I liked most about the 4100NH is it’s easily accessed brushes. Located at the end of the saw, you are just a flat head screw driver away from replacing the brushes when they have been used up. Other saws like the Hitachi require removal of the bottom casing to access the brushes while the Makita has them right there.

This feature is definitely a plus when your saw requires a quick service and time is of the essence. I have had brushes give out on me during the busiest of days so it is definitely something to consider.

The price is also very competitive for a professional brand saw. For it’s capability as a workhorse the price is very affordable and could readily be picked up by any contractor needing such a tool.

Unfortunately these features are not enough for me to consider purchasing the Makita 4100NH and why it ranked last in my comparison.

Remember this is a test for the best tile saw, so I aimed it for sole use as a tool for tilers. However it has great capability to be used in other trades.

The Parts That Let Down The 4100NH

The major flaw with this masonry tile saw is it’s lack of wet cutting ability.

Considering all the saws I am comparing are all within the same price range bar the other Makita, I do not see why the 4100NH didn’t come with the valve and plumbing to equip it for wet cutting.

Also the safety off toggle switch for the thumb is of cheaper quality when compared to the others. I have had many instances where it was difficult to push in the button and required multiple attempts, while this isn’t a game breaker for most, it is definitely an extra annoyance in a stressful day.

Styling and Design of The 4100NH

While styling is a subjective thing where beauty is in the eye of the beholder, I do not particularly like this design. It is very simple with no real design elements or flair. Just a plain blue colored plastic all throughout.

The other Makita on review at least has ribbing on the handle that adds grip and visual interest and the Hitachi is just the king of cool in this comparison. Dramatic contrast, modern and aggressive styling and plenty of rubber grips everywhere.

This design makes me think of Makita’s cheaper entry level tools usually featured in a green colour. While it may be a professional tool, the styling says casual DIYER.

Quick Summary of The 4100NH

While I believe this masonry tile saw may not be the ideal saw for a Tiler, it will be right at home for a landscaper cutting concrete pavers and possibly a granite kitchen installer along with all the others listed above.

It has all the grunt required to cut such materials and the lack of wet cutting shouldn’t be missed when used in this application. The operator always can have an assistant spray water onto the material during cutting.

For the price it is a great saw and can have life as a professional’s tool. It being fourth place in this comparison does not make it a loser in any regard. It is just outranked by the others simply due to it’s overall versatility.

Alternative – Makita 4100KB Dry Masonry Saw with Dust Extraction

It has recently come to my attention that there is a sub-model of this masonry saw, designed especially for dustless cutting of masonry and tiles in sensitive environments.

If you cutting in sensitive environments and want a completely dust-free saw, this one is for you. Also, those that dry-cut tiles should give this one a look as well.

I dry-cut 99% of all tiles, so don’t think you need a wet saw for everything. I only wet-cut thick or very long tiles. This is to keep the blade cool, prolonging it’s life and increase cutting speed.

The 4100KB is an upgraded and revised model to the 4100NH which I reviewed however it also has a purpose built dust shroud and extraction nozzle that you can either fit a dust bag (included) or simply plug in your shop vac for the best dust extraction possible.

For cutting in residential homes or any place that you can’t make a mess with all that flying dust, then this dustless masonry saw is definitely the one to go for. With more stability and power over an angle grinder, this will be a game changer for anyone that cuts masonry on site.

Those working with cement board will be particularly in love. This is THE SAW TO CUT CEMENT BOARD!

Lastly, it can accommodate larger 5” blades.

In 3rd Place – DeWalt DWC860W

Quick Specs:

Motor power: 10.8 Amps (1188 watts)

Max RPM: 13 000 rpm

Weight: 6.6lbs (3.0kg)

Depth Gauge Included: Yes

Diamond Blade Included: Yes

Wet Cutting: Yes.

Pros:

- Cheapest wet cutting saw in this comparison.

- Additional bevel feature for cuts up to 45 Degrees – Only saw to feature this.

- Easy access to brushes

Cons:

- Diamond Blade supplied is inadequate for cutting tile.

- Sub standard water valve unable to fully stop water

- Bad water fittings.

- The heaviest in the group being compared.

Who Should Use This Saw:

- Brick Layers

- Casual Users

- DIYers

- Contractors working with Cement Board

- Tilers requiring a wet cutting back up saw

Taking a Closer Look at the DeWalt DWC860W

I have many DeWalt power tools in my arsenal for daily work and home duties. From their excellent 18volt XRP battery system which runs cordless drills to a work site radio, circular saw and others, so when I picked this saw up I was expecting the same amount of professional design and capability.

After all, their a home grown American company that started manufacturing tools for good folks since 1924, they definitely know a thing or two about making a tool right?

Well yes and no when it comes to the DeWalt DWC860W

Unfortunately it seems Dewalt took a shortcut in Research and Development and put a semi-professional product out for sale. From what I can tell this is DeWalt’s first foray into the tile saw and they may have a few things to learn.

While it has a decent modern motor with a high RPM (13 000 rpm) and a nice cut adjustment system, everything else is marred by cheap design.

Let’s start with the negative first and work our way up to the cream. Or if your a steak man, let’s eat the veges and mash first, then save the meat for last.

The Parts That Let Down The DWC860W

Before we begin I would like to point out this handheld tile saw WON a few tile saw comparison reviews.

I am at a loss as to how the reviewers came to this conclusion.

As a tradesman working with such tools daily, I can’t help but think they never even saw the handheld tile saws let alone actually used one.

Instances like that were what made me make this website in the first place.

Let’s get back to the DWC860W and it’s faults that were omitted in other online reviews.

The pressure switch is very small compared to others and a lack of rubber shielding allows dust to enter the switch mechanism during use.

Over time this dust will solidify to a rock that will make the switch hard to operate or jam it completely.

If you are working with concrete pavers this is a particular concern as your cuts create the thickest cloud of dust. The sludge created during wet cutting can also scum up this mechanism, something you should make sure to wipe off during work with stone materials.

The arbor size is usually the same on all masonry tile saws at ¾ inches however DeWalt has used a different size that may cause trouble finding a diamond blade for it if an arbor adapter isn’t included.

The inadequate wet cutting system!

I believe the wet cutting system is the biggest let down of the saw and in fairness it should really place this saw at 4th place simply to the fact it is so poorly built.

Cheap plastic abounds a system that requires it to be water tight. Which this saw unfortunately isn’t.

You can attempt to close the water flow completely at the saw but even at the tightest setting water still flows. I do not see the point in including a tap if it doesn’t even work.

So in a practical stand point, every time you go to cut your material you need to walk over to the water supply line and turn on the water then run back to where the saw is before it drenches itself.

Then after making the cut you need to shut off the water again. I think you can see the problem here.

In a normal work day where you can easily make over fifty cuts or more, I cannot live with such a time waste and hassle. Also the water jet doesn’t supply adequate water onto the diamond blade, this is a concern when cutting particularly dense materials.

The plastic fantastic continues onto the hose fittings which are also plastic and of cheaper quality. For a reputable company this is disappointing to see and hopefully this will be addressed in the next generation of saws.

Phew, that was a lot of veges! Broccoli and brussel sprouts even. Now that we chowed down the worst part, let’s enjoy our prime steak.

The Best Parts I like About The DWC860W

On a positive note I enjoyed the inclusion of a Lock-On button that will keep the saw operating without pressing the switch continuously.

I love this feature as on those nightmare days where I am cutting for long periods of time, I find my hand starts to loose strength holding that button for extended periods.

Many times I have longed for this feature and DeWalt have heard my prayers.

DeWalt have also made the brushes easy to access on the exposed outside of the saw. This results in less down time when the brushes wear out.

Due to this being a wet saw I hope the threads are water tight to keep the internal magneto dry in case any water splashes near that area. Considering the quality of the water feed system, it very well may happen.

The saw also features a beveling cutting system which may prove very handy for miter cutting in a wide range of materials. If you require a masonry saw with this capability, you are in luck!

Quick Summary of The DWC860W

This wet or dry power saw could have a life as a tilers saw with it’s easy access brushes, Lock-On button and nice 13 000 rpm motor, however if you need to do a lot of wet cutting I would give this one a pass.

Nice overall design and styling cues give this masonry tile saw a professional look but a few dollars skipped in R&D hindered this saw from being a proper daily saw in my eyes.

Pricing is reasonable and could suit a more casual user or someone working with concrete pavers or sheeting, work with stone materials should be kept to a minimum. The beveling system is a unique feature on this saw and could be a winner for some. It’s a great saw for mostly dry cuts and the occasional wet cuts.

Do you think the DeWalt DWC860W is the right saw for you? You can get it here in time for your next project.

In 2nd Place – Makita 4101RH

Quick Specs:

Motor power: 7.9AMPs (1,050 watts)

Max RPM: 13,800rpm

Weight: 6.5lbs (2.9kg)

Depth Gauge Included: Yes

Blade Included: Yes

Wet Cutting: Yes.

Pros:

- Great Build Quality

- Purpose built back cover to prevent water ingress

- GFCI Plug built into cable

- Great wet cutting setup

Cons:

- Nearly double the price of others in comparison

- Weakest motor in the comparison group

Who Should Use This Saw:

- Brick Layers

- Kitchen Installers

- Stone Masons

- Tilers requiring a dependable work horse with superior wet cutting ability

Taking a Closer Look at the Makita 4101RH

This is more of what I expect from a power tool giant like Makita. The 4101RH is a well-engineered piece of brilliance from the Japanese giant.

Makita firmly believes in the philosophy that “if it ain’t broke, don’t fix it” as I owned this exact saw back in the 90’s!

It may have had a few updates over the years but on the outside it looks identical to my old Maki’ from the distant days gone past.

I surely do not remember the inclusion of a ground fault interrupter on the power cord back when I had one. This is a very commendable move on Makita’s part as they are addressing the extreme safety risk that is water and electricity in close proximity to each other. If you work with stone materials and wet cut a lot, OSHA will love you.

Let’s address the best bits of this all round great saw.

The Best Parts I like About The 4101RH

The Makita 4101RH has the best safety features I have seen on any saw simply due to the fact Makita is addressing the issue of water and electricity with proper concern.

Since this is a tile masonry saw with wet cutting capabilities, Makita understands that water may go where it shouldn’t and cause a massive and life threatening problem.

Hence with the inclusion or the GFCI or a RCD as it’s known in other parts of the world, if the unforeseen may happen and electricity flows somewhere where it shouldn’t (up your arm for example) then the switch will trip and instantly shut off any electricity coming to the saw.

Effectively saving your life or a severe burn.

Hat’s off to you Makita.

While I have seen this feature on other saws, I like its particular inclusion on a specified wet cutting saw. Makita doesn’t stop there with the water safety as they have also included a specially designed cover for the rear motor to make sure no water gets in there.

The rear of the saw is particularly susceptible to water as its main armature coil is located near the back air vents. This cover protects the heart of the saw in case of stray water finding its way there. Considering that’s where the electricity is generated, it’s a wise decision to have it there.

This design feature has been around since the 90’s.

I always found it humorous that the cover was held in place by a hose clamp, it almost looks haggard like a zip tie holding your car bumper on.

Obviously the system works as it has remained a feature over the decades so I am no one to judge it’s inclusion.

Let’s dive right into the cream shall we, and talk about that wet cutting setup.

Best wet cutting setup!

Apart from safety the Makita also features a brilliant water system included with the tile saw.

Along with all the regular fittings that are made of quality metal materials on the saw itself, Makita also throws in 15 feet (4.5 metres) of water tubing, a water pressure regulator and a water valve.

No one competitor receives all these extras and this truly makes the Makita the superior in wet cutting abilities. Having a water pressure regulator should prevent any leakage problems due to excess water pressure coming from the supply and ensure you get the water only where you need it.

Of course all good things must come to an end and all that indulging in cream comes at a price.

The Parts That Let Down The 4101RH

All these aforementioned goodies do come at a price as this tile masonry saw is the most expensive in my test by a wide margin.

For the price of this saw you could purchase two of the previously tested Makita 4100NH’s (according to prices at time of comparison). Make sure to keep that in mind.

However while the cheaper 4100NH is more of an entry level tool, this 4101RH is pure professional and if you require a reliable wet saw for your job the price is easily justified and feasible.

It is the price point alone that affects the 4101H from achieving a top rank in this review. While it is great to have a well-built wet saw, I am looking for the best daily tile saw for Tiling.

Quick Summary of The 4101RH

If you are a stone mason or anyone working with natural stone a lot then this would be the masonry tile saw for you. The price will easily pay itself off in no time and you will be sure it can perform hard all day for many years to come.

The inclusion of a GFCI saves you from purchasing one and will keep OSHA and any work site foremen happy as well as your families when you return home that evening.

A tried and true classic, the 4101RH is a reminder of the times when Makita only made the best tools and stuck exclusively to manufacturing only in its Japanese homeland. While those days are now long gone, this saw still retains the old formula and reliability one can rely on every day.

Do you think the Makita 4101RH is the right saw for you? You can get it here in time for your next project.

In 1st Place – Hitachi CM4SB2

Quick Specs:

Motor power: 11.6 Amps (2,090 watts)

Max RPM: 11.500rpm

Weight: 6.2lbs (2.8kg)

Depth Gauge Included: Yes

Diamond Blade Included: Yes (if selected at checkout)

Wet Cutting: Yes (Some stores sell it without the water plug. See below for details.)

Pros:

- Dust proof switch

- Lightest saw in class

- Highest power in class

- Similar price to others in class, half the price of Makita 4101RH

- Most modern engine with innovations to promote long life

Cons:

- Time consuming to replace brushes

- It dosen’t float

Who Should Use This Saw:

- Everyone!

- Tilers requiring a reliable and versatile work horse for everyday

- Brick Layers

- Contractors working with cement board

- Landscapers

- Any one working with Pavers

- DIYers

- Casual Users

- Stone Masons

- Kitchen Installers

Taking a Closer Look at the Hitachi CM4SB2

Ladies and gentlemen meet your champion and the fallen hero that fell into a bucket of water. When I set out to find a replacement for my Hitachi CM4SB2 I didn’t expect to end up purchasing another one.

Since my Hitachi tile saw was around 5 years old before it met its early demise and I thought there would be newer and better models available.

After researching and testing I was proved wrong, and how very wrong indeed!

It seems handheld tile saws are neither as a competitive nor as a hot market as a drill driver for example so manufacturers put out new models much less rarely then they do popular tools.

Which is understandable from their view point but that sadly means we miss out on getting the latest goodies for our trades.

Nonetheless, when Hitachi set about creating their version of a handheld tile saw they looked at what the other competitors were doing and simply made it better.

How much better is the CM4SB2?

Well for starters the CM4SB2 (try saying that in a hurry!) is the class leader when it comes to motor power, with a massive 11.6 amps (2,090 watts) of power output coming from its modern power plant.

The max rpm is the lowest at 11,500 yet I believe this adds stability during cutting as you get a stronger cut with less vibration coming from excessively high rpm.

During cutting of any material I found the Hitachi tile saw to be the most stable and controllable and with a class leading weight rating of only 6.2lbs (2.8kg) it is the lightest in its class which also adds to its outstanding stability.

Hitachi has done more than just that however.

Unlike the other handheld tile saws, the CM4SB2 has a sealed armature core which protects it from the daily assault of dust and debris created from cutting tile, concrete and stone.

What’s an armature core you wonder?

The armature core is the central component of the electrical motor. It carries current across the electromagnets that live around it and creates an electromotive force, which in turns makes torque. This torque (or spinning force) is applied to the shaft which spins our diamond blade and enables us to cut!

Did I lose you there? Sorry, I’m no electrical engineer myself but I tried to make it as simple to understand as possible.

At the end of the day what it means to us is, since that core is sealed from any outside elements, this keeps it protected and safe to do its job in a controlled environment.

This means it will be working at optimal performance for much longer compared to other unsealed masonry tile saws.

How long you might be wondering? Well my unit was going on 5 years and still ran like a champ with no vibration or loss of power. If it didn’t take a dunk in the bucket I believe it could have easily gone for longer.

The One Bit that Let Down The CM4SB2

The brushes for the saw are the most difficult to access out of all the saws tested. I would put this down to the sealed armature core featured in it.

And by difficult I mean it requires you to undo two Philips head screws and popping off the bottom plate.

A chimp could do it.

After taking that off you have access to the two flat head screws to reach the brushes.

This operation is rare as brushes can last easily from a year or more depending on usage.

I use my Hitachi tile saw daily for multiple cuts and I can easily get a year or more use out of a single pair.

So don’t let this concern you. The added benefit of a sealed core far outweighs the extra two minutes it requires to undo then tighten up two screws.

The Bits I Like About The CM4SB2

This sealed armature core also aids in keeping vibrations from this motor down. Remember that the core is rotating its central shaft at over 11,000 times per minute, so having the vibrations dampened and keeping your hand steadier is a big plus.

This factor also confirms why its better having a slower rpm rating as well; excess speed will create excess vibrations.

The Hitachi CM4SB2 is also the only one to feature a dust sealed pressure switch.

This is basically a big rubber glove over the trigger that allows easy pressure but is fully sealed against all the dust you will be making during a cut. A simple feature which helps keep the saw running for longer without replacing the main switch.

Now the Hitachi CM4SB2 wouldn’t be the top rated and best tile masonry saw if it wasn’t equipped for wet cutting so yes it does come with wet capability.

Hitachi provides you with a simple tap that fully cuts water on and off.

I would have preferred if the tap was bigger as it can be hard to turn on and off, this is where the Makita 4101RH trumps over it. As that saw has simply the best system however the Hitachi still manages to get the job done.

Along with the water valve you receive vinyl hose, a water plug and rubber connector. While it is not the best feature of the Hitachi CM4SB2 they get the job done.

The water jet is powerful and supplies the saw with plenty of water during a cut. I have never had problems with a lack of lubrication and I can always adjust the flow via the tap located near the blade.

Like all over handheld tile saws you also get a depth adjustment plate to control depth however with the Hitachi you cannot control the bevel for angled cuts like you can with the DeWalt.

Do You Want to Know a Secret? I Actually Owned Two CM4SB2’s.

Meet Slim Jim and Wet Willy. My two Hitachi CM4SB2’s. Equipped for different duites they are my go-to team for most cutting duties

The one that got fried was one equipped for wet cutting but I also have one with all wet cutting gear stripped off along with the angle plate.

This was my everyday work horse used for cutting most common types of tiles like ceramic and porcelain that don’t require depth adjustment or wet cutting.

I found the saw much easier to use due to it’s lower weight and manoeuvrability compared to the unit with all those extras.

If you are like me and require the use of a handheld tile saw every day I would recommend you also have a setup like this.

That way your day to day life is easier with a lighter saw but also if it goes down for whatever reason, just pull out the other and you can continue with your work.

What do you reckon I did after my wet cutting Hitachi CM4SB2 took a dunk?

I grabbed my everyday Hitachi tile saw, refitted the wet cutting components and got back to work. That way I still got the job done and my work schedule wasn’t affected due to this mishap.

The Hitachi CM4SB2 is also available at a great price which just seals the deal for me.

Over a few extra bucks over a entry level QEP tile saw I can have the best handheld tile saw available.

It’s a no brainer.

Quick Summary of The CM4SB2

At time of writing the saw was in the same price region as all saws reviewed except for the highly priced Makita 4101RH.

This should make it incredibly tempting for all you that are requiring a solid and reliable everyday handheld tile saw with wet cutting ability.

Not only will it out perform all overs but also remain by your side for many years to come.

Buy some diamond blades and a spare set of brushes and your set.

I would recommend this tile saw to anyone working with masonry, tile or concrete and wants a tool guaranteed to do the job.

It has the most power to get through any material you throw at it along with the greatest stability due to its internal core shielding and lower rpm range.

Do you think the Hitachi CM4SB2 is the right saw for you? You can get it here in time for your next project.

2025 Update on the Sale of the Hitachi CM4SB2:

1 – Due to corporate restructuring, the CM4SB2 now carries the Metabo name, it’s still the same Hitachi tile saw and made to the same standards.

2 – It appears that online sellers of the Hitachi CM4SB2 do not include the few parts needed to make this hand held tile saw a wet cutting saw.

As it is currently sold, it is a dry cutting tile saw only but I have found the parts needed to make the Hitachi CM4SB2 Wet Saw Ready.

The parts are easy to get and I truly believe it is worth the extra fistful of spare change to buy the part and get the Hitachi tile saw and use it as a wet or dry cutting tile saw.

To turn the Hitachi CM4SB2 into a wet cutting tile saw you will require:

Water Plug

This part attaches to your tile saw with a screw that is supplied.

It features twin water jets that spray water directly onto the diamond blade and allows a vinyl hose to connect onto it that feeds the water.

There is a watertight on/off valve that allows you to adjust water pressure and shut it off completely when required.

Rubber Connector

This part allows a vinyl hose to connect to a water spigot/tap located on a house.

It threads on like a normal hose adapter and allows you to use the house water supply to run your wet saw.

The metal rod allows a vinyl hose to be slipped on the end of it. You slip the other end of the hose onto the water plug.

Vinyl Hose

This is a standard issue vinyl hose that Hitachi makes for their CM4SB2 Tile Saw.

It has the right diameter to fit the water plug and rubber connector and together with those two parts, turns the tile saw into a wet saw.

These three parts are what you require to make your Hitachi Tile Saw a true wet cutting saw.

All parts are available at Amazon along with the tile saw so if you are wanting a wet saw, just add these three parts to your cart when ordering the Hitachi CM4SB2.

If you want a more flexible wet saw that you can use away from a spigot/tap, I recommend to not purchase the rubber connector, and instead purchase a basic water pump.

It draws water from a bucket or other container and allows you to setup a cutting area wherever it is handy.

Since you will be wet cutting, it’s advisable to cut away from a driveway or other finished areas that will get dirty from the used water that contains all your saw dust and other debris.

This water pump allows you to do that as it’s much easier to run an extension lead rather than a super long piece of vinyl hose.

Just setup in a easy to clean-up area like a lawn and you’ll be good to go!

Water Pump.

This is a basic water pump designed for submersible use.

It recirculates the water when not in use and can be left on for long periods of time.

Simply drop it in a container of water and connect the hose to your tile saw.

Keep a second bucket of water nearby to top up the main bucket when needed as you do not want the water level to drop below the level of the pump.

Meet the tile saw with three names. Depending on your market, the CM4SB2 goes under three brand names.

1. Metabo CM4SB2

2. Hikoki CM4SB2

3. Hitachi CM4SB2 (now discontinued.)

They are the exact same tile saw, but because of a corporate restructuring that eliminated the Hitachi name, they are now sold under different brand names, depending on the market. Hikoki owns Metabo as well.

I own both models and they are exactly the same!

How To Setup The Hitachi CM4SB2 For Wet Cutting – Wet Saw Tutorial Video

Since releasing this review, I have had a number of questions on how to actually put all the wet cutting components together and equip the Hitachi CM4SB2 tile saw for wet cutting.

Since I love you guys so much, my wife and I shot this quick tutorial video for you. It takes you step-by-step and shows you how to install the water plugs and valves. It’s super easy and this video makes it even easier.

Oh, and Jane’s brother narrated the video, sadly we couldn’t afford to hire Morgan Freeman! (Keep supporting this website, and maybe one day we can!

Wrapping Up My Great Hand Held Tile Saw Comparison

In conclusion I am very surprised with the current availability of professional handheld tile saws.

Overall there is a raft of great machines provided by all the major manufacturers making selecting the right one a difficult decision.

I hope this comparison review provided you with the knowledge into which saw you would like to purchase and maybe learned a thing or two.

Handheld tile Saws appear to be a field with a much lower development cycle compared to other fields, as shown by the old but reliable 4101RH. A model is expected to last for at least ten years without any major revisions and it’s sad to see this great power tool being so under-utlized.

When I set out to find the best handheld tile saw I did not expect to replace my old Hitachi CM4SB2 with another one.

I thought surely a new machine would have surpassed it’s capabilities in the years since I purchased it.

I did not let my familiarity with this saw sway my opinion or affect it in anyway; I would have just as happily purchased a DeWalt DWC860W if I had found out it was better.

In the end it was the Hitachi’s greater power, innovative motor design and overall functionality combined with reliability that made me decide on purchasing another.

If you have never owned a Hitachi tile saw then the CM4SB2 is a great example of what this company is capable of making and it might even surprise you.

The Hitachi CM4SB2 is the best handheld tile saw period, grab one for your work and you will agree.

The CM4SB2 is available at Amazon along with all the other saws reviewed today. While you are there be sure to add a diamond blade or two to your cart so you are ready for your next project.

Happy Cutting!

The Quest to Find The Best Tile Saw

Did you ever have one of those days that you wished you never got out of bed?

Did you step out into that great wild world beyond your door to earn some bread but it seemed every move you made just kept making life more complicated?

Yeah you know the ones, those days.

I just had one of those days and now find myself in a dilemma as I lost my most essential tool to a freak accident and now require a new one ASAP! Like, I need one today, yesterday if possible.

If I had just stayed in my warm bed with my equally warm wife I could have avoided all this hassle and my day could have had a happy ending. Take that in whichever way you want, I know how your mind works.

Instead, I went to work like a good boy and by lunchtime my tile saw was in the bottom of a bucket full of water, hissing and frying its last seconds.

How did it get down there you may ask?

Well put simply, a busy work site with too many contractors working at once is not a good combination for anything. Let alone tools left on a workbench, especially masonry tile saws equipped for wet cutting.

A careless painter with a ladder bigger than his brains waddled past and like a slapstick comedy the end of the ladder connected with my Hitachi tile saw.

Pushing it cleanly into my bucket of water I had for the water pump to work in.

I knew my saw was in trouble when the instant all the work lamps went out and the music from the work site radios stopped.

After the fuse breakers were reset and the masonry saw disconnected from any power I quickly discovered my trusty saw just bit a watery death.

The insides smelt like burnt toast and ozone and were equally as black, the diamond blade also had a crack in it. Fantastic…

So now I am on the hunt for a new hand held tile saw and diamond blade to replace my old Hitachi and since the painter is paying for it; I can choose whichever one I want.

Like a kid in a candy store.

Hand-Held Tile Saw Draw Backs

The biggest drawback I can pin point with a handheld tile saw is that it requires practice and discipline to get a perfect result. You won’t be cutting perfectly straight lines on your first go, it’s best to practice on scrap material or on cuts that won’t be visible.

Don’t let this scare you away from getting one though, just be sure to practice with it before making any money-maker cuts. I use one of these wet tile saws on a daily basis and I feel I know my way around one pretty well, within time, so will you.

If you have experience cutting with an angle grinder, then cutting with a hand held tile saw should be easy and come naturally, the principles are mostly the same.

Another gripe I have with these fantastic power tools is changing the diamond blade. The way the saw is designed means you require a couple tools to loosen the central bolt to access the diamond blade. I hope that future designs allow you to replace them quicker like angle grinders. A lock-on button for longer cuts would be nice as well.

Masonry And Tile Saw Information Center

Tile saws are also commonly known as:

- Masonry Saw

- Electric Tile Cutter

- Wet Tile Saw

- Handheld tile saw.

- Wet Saw

- Portable tile saw

- Dry Cut Masonry Saw

If you refer to this machine as any of those names then my list applies to you as they are one and the same thing.

Just apply the type of diamond blade suited for cutting your material.

What is a Handheld Tile Saw?

A handheld masonry saw or tile saw is a small electrical saw similar in design to a circular saw but it is much smaller and designed for single handed use.

It features a large handle at the top with the motor and cutting surface located perpendicularly beneath your hand.

This offers great control of the saw during a cut as it forces you hand to go down not sideways.

This is imperative during cutting hard materials as any sideways pressure while your saw is inside the material may lead to the diamond blade exploding.

Have you ever moved your hand around while holding an angle grinder?

You can feel the way it wants to pull sideways, a tile saw does not have this sensation making it much more stable to use.

I have cut many tiles on both an angle grinder and tile saw and prefer the saw ten times over a grinder.

Nothing compares to the control and stability of this machine.

You have a pressure sensitive trigger beneath your finger so if you drop it, it will shut off, unlike a grinder that may keep running due to its snap lock switch.

You also have a much sturdier grip thanks to the large handle your hand can wrap around.

When cutting tiles I feel the grinders’ excessive rpms makes the machine pull away from the surface during a cut. (Of course you can buy a grinder with variable revs to counter this problem.)

This makes you wrestle it towards the surface whereas a tile saws extra weight and different cutting angle makes it hold its line much better.

Please note that not all angle grinders have high revs, some models like the DeWalt DWE4557 offer a low 8500 max rpm or others like the Bosch GWS13-50VSP have a variable speed function which allows you to control the max speed.

The advantage a grinder has over a handheld tile saw is it lighter weight which makes it easier to hold for longer periods and makes it easier to control for trickier cuts. Tilers doing the fancy scribe cuts will enjoy using a grinder for this very reason.

Another is it’s ease and speed of changing a diamond blade on the grinder, whilst a professional tile saw takes a couple tools and care to replace.

If you want a tutorial how to change a diamond blade on a handheld tile saw, or to replace the brushes, follow the links or use the search bar above..

I will let you be the judge but I prefer to leave my grinder well clear of any tile cutting duties. Many fellow tilers swear by grinders but I bet they haven’t given a handheld tile saw a go.

One more feature the grinder is lacking is in wet cutting ability.

You cannot attach a water valve to the grinder so the only cuts you can make a dry. While this is not a game breaker, it definitely cuts the angle grinder’s versatility in half.

Once you try a tile saw, there ain’t anything more. (My wife says I am a terrible poet, can you tell?)

Material cutting with a handheld tile saw is done thanks to metal blades reinforced with diamonds. Hence the name, diamond blade. Industrial diamonds are embedded in the cutting area of the blade which enables the small saw to cut through extremely tough materials like:

- Concrete, (including aerated concrete blocks for shower upstand ledges)

- Asphalt,

- Brick,

- Masonry (hence the name)

And most importantly for us in the tile industry,

Tiles.

And not just a specific type of tile but as my experience had shown there hasn’t been a tile material I could not cut with a tile saw.

From standard ceramic and dry pressed tiles to all forms of vitrified porcelains no matter the thickness.I usually leave the cutting of such tiles to a tile cutter like my TX-900N.

However any special cuts, essentially anything that isn’t a straight cut I handle that on my tile saw.

Need a circular hole cut for a water pipe?

No problem! After marking the position on your tile etch around the circle using the diamond blade. Just enough to penetrate the glaze, then cut into the center of the tile, aiming to get your diamond blade all the way through to the other side.

Round cuts are easy on a Tile Saw. With small etches done around the radius you can then cut out the interior.

Once you have enough material cut out you will be able to insert some tile nippers to pinch out the excess material.

I have been doing this for many years and found it is the quickest and easiest way for making such holes.

If you take care you can get a perfect round hole. It’s definitely an essential skill to add if you haven’t already.

All thanks to a tile saw.

However the masonry tile saw isn’t only capable of cutting such common tile types, it is also supremely capable of cutting tiles made from natural stone.

- Granite,

- Limestone

- Travertine,

And Marble are just a few examples of what a good tile saw can cut.

Granted if you want capabilities like this you need a wet tile saw with a water valve system built into it.

This system allows you to pipe water directly onto the diamond blade to keep it cool and lubricated while performing a cut.

This is essential for cutting thick material or long tiles like 24x24inch (60x60cm) or bigger. This is due to the extended running time of the diamond blade causes it to heat up excessively.

Lack of water to such a cut will result in factors like:

- Tile glaze melting off- often ruining the tile .

- Diamond blade unable to cut

- Diamond blade getting damaged and ruined

- Diamond blade exploding (very rare cases).

Water lubrication during cutting also helps eliminate dust during cutting.

As there are no tile saws available off the shelf with a dust shroud, water is a great way to control dust during cutting.

The water catches the dust instantly and turns it into a heavy powder, thus disabling it to enter the air and creating a cloud.

What’s a dust shroud?

A dust shroud is a plastic cowl that fits onto a head of a tool like an angle grinder. It has a large spout that allows a vacuum cleaner head to fit into the hole. When in use the vacuum sucks all the dust as it is created hence eliminating all dust created during a cut.

A grinder fitted with an after market dust shroud. Offering optimal dust extraction when coupled with a vacuum cleaner

Don’t have a cowl but have a buddy?

If you require a dry cut with zero dust then there is a way!

Have a person hold a vacuum cleaner hose near the cut line while you perform the cut. If the vacuum is running properly it should be able to suck up most of the dust even if it’s a few inches away. I have used this method before when circumstances forced me to cut indoors.

It’s not the best method, but it works!

Another feature of a wet tile saw is its small size and versatility.

Since there is no large table to setup and due to its small weight you can cut your materials in much less space over a full table saw.

This allows for quick setup every morning and an easy pack down at the end.

Spread out a drop sheet, run out a power cord and plug her in and your set.

This is great when working in a private residence or even apartment block where (if you’re lucky) you only have small balcony to cut on outside.

I have to mention however that I add another element to this to enable much easier cutting and not to mention to save my back.

I use a folding workbench like this Kreg KWS1000 Mobile Project Center.

This bench allows me to cut my tiles while keeping the material stable and supported.

After years of cutting on buckets or my knee, a folding workbench is a much needed addition. Due to its folding design it fits in the back of my work truck without issue.

If you haven’t got a folding work bench yet I highly recommend you get one along with your purchase of a handheld tile saw. It’s worth its weight in gold. You can thank me later.

The last point I would like to make is that a tile saw is not just limited to Tilers.

Most stone masons or kitchen installers I know have one. They are predominately working with stone so require a compact yet powerful saw to cut their materials with.

Landscapers and any paver setters also have one as the tile masonry saw is extremely capable of cutting concrete pavers and stones for their work.

Brick layers use them to make quick cuts and details in bricks and similar materials.

Another common use for a masonry tile saw is cutting cement board, equipped with a regular diamond blade it flies through, making the job effortless.

This versatility comes with the amazing assortment of blades available on the market in a range of styles and price points. The general rule of thumb is the cheaper it is the softer the material it can cut and its durability is nowhere near as lasting as a proper blade.

There are many different blade finishes in a tile saw blade. This is just a select few or a vast array.

Generally if you find a good blade it can last anywhere from 3 to 6 months or more, cutting tiles daily in a variety of grades.

I have found great results from turbo blades such as this one and prefer to use them over mesh designs due to turbos having a wider cutting area. Check out some diamond blades while you shop and be sure to add to cart!

This helps keeps the blade cool from extra air flow and less rubbing from the majority of the blade.

Remember when purchasing a blade that you buy the corresponding size blade.

The handheld tile saws we will be viewing today should all work with a standard 4inch blade. Also note the center hole is large enough to accommodate the center shaft/arbor of your saw.

Most blades come with a washer to accommodate the arbor of a masonry tile saw or a grinder. The previously mention turbo blade is ideal for your saw.

Tilersplace 2025 All Rights Reserved.

I think I need a beer after readin all of that! Phew!

Gotta say that is one of the most comprehensive reviews I have ever read on any power tool, let alone a masonry saw! Thanks for this quide Carl, I was tossing up between getting the Dewalt or that cheaper Makita as their available at my local hardware store. Now I’m seriously thinking about getting that Hitachi. I own a few of their things and am happy so why not!

I’m gonna have that beer and take the plunge, judging by the review it’ll cut everything I need it to with ease.

Thanks for reading Paul, if you got to the end you definitely deserve that beer!

I’m glad you are liking the content so far! I am trying my best to provide the most thorough and honest reviews for us like-minded guys and gals on the internet. Definitely a tall order I know but I’m gonna try. I’m motivated by the fact that it’s so hard to find decent reviews for our tools so I want to put a stop to that and create a resource of quality reviews.

Ha! The Hitachi is hard value to pass up my friend, I didn’t realize it myself till I began work on this review.

Let me know how you get on with it, I’m confident I didn’t steer you wrong.

Keep the reviews coming Carl, I’m really enjoying reading them so far.

Really glad I discovered this site as a tiler and stone worker myself it’s great to read reviews from someone else in the industry- and someone who knows what they’re on about!

I have owned a Makita 4101 wet saw for a number of years now and it’s great to see my old buddy score so well in your review. Although I wish it came out on top I see why the Hitachi was the overall winner. It really seems to be the king of versatility and that price will get any ones dogs barking. You did call the Maki the best wet saw so still a win in my eyes!

I laughed when I read the design hasn’t changed since the 90’s, I didn’t know that! I guess Makita knew they have a great product and don’t need to revise it. The day they do however is when I will retire my old one to secondary duty.

Barry! Hope that Saw Shack is working out great for you.

I’m pleased my site is proving to be of value to you my friend, make sure to keep coming back to read all the latest reviews. I have big plans for the site so it will only keep getting better!

Your a wise man to be using the Makita 4101, it’s a damn fine wet cutting saw so I can’t fault you on your choice.

Happy to hear I got a laugh! Yes it’s quite interesting how the design is so similar for all these years. Makita designed its saw for the ages!

I’m looking forward to the day Makita updates the 4101, it will be fun reviewing the new design. I can’t wait to get my hands on it whenever it arrives.

Totaly agree with you about the angle grinders Carl. I have seen many guys throwing a diamond blade on them and cutting hard materials. more than once have I argued with them especially if they ended up chipping the material which was often.

I remember a kitchen installer nearly killed himself with a diamond blade grenade when the grinder bucked and twisted while cutting granite and the blade exploded. One piece of the blade was buried in the wall. If that guy was my worker I’d have given him a smack over the head as congratulations for surviving that. If you need to cut, get a masonry saw! It’s what they are their for. save the grinders for grinding. Not so hard to remember kid.

Hey Chris,

Ouch! That must have been a scene for sure. Total luck that fool didn’t end up with blade shrapnel in his dome or stomach.

If I witnessed that I would have given him a whack for endangering my life and any other contractor on the site.

As you said there is simply no other tool that can rival the saw in terms of cutting. It is just the most stable and adept during thick cuts.

Carl, thanks for so much thorough information. I’m going to try the Hitachi 303648, and I read your 2018 update. I am a bit confused: Most online retailers, including amazon, now call this a “dry cut” saw. I’m assuming that buying and attaching the water plug is a necessity…but what else is needed to use it as a wet saw? The acrylic hose? Then how does it connect to a water spigot/faucet, or is it necessary to also purchase a water pump? Thanks for your help!

Hi Peter, please check your other comment below, I have replied to both your questions there 🙂

I also found the Hitachi Rubber Connector Wet Cut Part Number: 956-885, which I assume attaches to the spigot? Will that part, along with the hose and the water plug, make me “wet saw ready”?

Hi there Peter, thanks for the comment and question.

Yes you are right, it appears on-line retailers only list the Hitachi CM4SB2 as a dry cut saw and do not include the few extra pieces that make it a wet cutting tile saw. I was very disappointed when I learned this as it hindered the true versatility of the Hitachi tile saw.

I see you have been doing some research on your own and yes you are right. I have consulted a Hitachi Part’s list and the three parts you have listed are what is needed for wet cutting.

To make the Hitachi CM4SB2 “wet saw ready” you will require:

The water plug – This screws onto the tile saw with a supplied screw and squirts water onto the blade.

A basic acrylic hose – This slips onto the inlet of the water plug and onto a rubber connector that attaches a spigot/water pump.

Rubber Connector – A basic rubber plug that threads onto a home spigot and allows the an acrylic hose to be slipped onto the end.

These three things, which used to come standard with the Hitachi CM4SB2 are the only parts needed to turn the dry cut tile saw into a wet cutting saw.

If you would like my personally opinion, a basic water pump is much easier to use instead of the spigot as it allows you to locate your cutting area where ever you want, and not near the water supply. I just throw the pump in a bucket of clean water near my station and leave it on all day. It recirculates so theres no worry of it burning up.

Once you are ready to cut a tile, simply turn the valve on the tile saws water plug, adjust the spray to a desired level and get to work. After you are done, just shut the valve off. It’s fully watertight as well.

I just top up the water bucket as needed from another bucket. This system is handy as I am not limited by the length of my vinyl hose nor do I need to cut near a water supply.

If this is not a concern to you, simply buy the rubber spigot connector and get your water feed directly from the wall. Just keep in mind to buy a long vinyl hose.

I hope that has answered your question Peter, I have had a couple guys email me asking the same question and they all ended up getting the Hitachi CM4SB2 with the water plug, vinyl hose and rubber connector. I believe one also purchased a water pump. I haven’t heard back from them so it’s safe to assume their saw’s were “wet saw ready!” with those extra parts.

To help alleviate any future confusion, I will update my review again and try simplify the information so that good folk like you can learn everything they need to know before making a decision.

If there’s anything else, please let me know.

Carl, thanks for the update. The Hitachi is on its way to me, along with the three parts. I’ll decide on a pump later. Your reviews are top notch! Keep ’em coming.

Thank you for the reviews. I am a complete novice and bought the Hitachi. I did buy the wet cutting saw components, but I have less than 10 cuts to make on a delicate porcelain tile and there are no instructions that I can find on how to set this up. In my mind, electricity and water don’t mix, so I need clear and precise instructions on how to avoid a catastrophe. I have no prior experience or knowledge to go on. I tried it dry, thinking it was less time consuming and I only needed to make a few simple cuts and it sparked like crazy and burned the white tile at the cut. I got about 1/4 inch into the cut and gave up. Is this the way it should work? Am not sure if I should be concerned with the level of sparking. Very frustrated…may have to hire a tile guy to make 10 cuts that I thought I could do with this saw. Thanks for any suggestions or pointers to the Hitachi wet tile setup.

Hi Katie

I’ll try help you as best as I can 🙂

Yes, you are totally correct, water and electricity should never mix as bad things happen when they do.

There are some basic precautions you can follow to help minimalize any water getting near your electrical supply. Firstly, place the plug you are drawing power from as far away from the source of water as possible. Preferably on the other side of your cutting area that has your water source. The Hitachi CM4SB2 is also fairly insulated from water so a few splashes on it should be okay however it’s best if you try avoid it as much as possible. Wipe away any water, etc. Also, make sure to always shut off the water plug on the tile saw whenever you are not using it. The water jets on the Tile saw are designed to only spray the tile blade if you adjust the valve on the waterplug correctly. Just crank it open a slight amount so the blade gets some water but doesn’t spray excessively. The waterplug I am mentioning is this part, the one that mounts to your Hitachi Tile Saw.

If you follow those precautions, you should be perfectly safe to use the wet cutting capabilities of your Hitachi CM4SB2. And yes, a GFCI should also be used in your power supply chain if you are not using one already. (It will shut off power if there are any faults like water splashes in the power supply).

Now, to make the Hitachi CM4SB2 ready for wet cutting. You need to install the waterplug onto the tile saw. It screws on with an included screw onto the area near the blade. If you take a look at this picture, it is the little black piece on the right side of the tile saw. There should be a threaded hole on your tile saw, ready to accept the screw. There’s only one way that the waterplug can be screwed in so hopefully you won’t have too much difficulty with this.

With the waterplug in place, you can now attach your vinyl hose onto the end of the waterplug. Just slide it over the nozzle that faces outwards until it cannot go in any more. The other end of the hose can be pushed onto the rubber connector.

This rubber connector can then be screwed onto your garden faucet of your home, similar to any other water fitting for your hose.

With those all connected, you can slightly turn on the water supply and see if it sprays onto your blade. If it does not, check the valve on the waterplug to see if it is shut off. Simply turn it to activate it.

I hope that give you a clearer picture on how to make the Hitachi CM4SB2 ready for wet cutting, if you are still having difficulty, I could try record a basic video of how it’s setup on my Hitachi.

Now about the burning tiles.

I know exactly what is going on as it happens to me as well. Firstly, are you pressing hard on the saw while cutting? The tile saw should be allowed to cut at it’s own pace, only light pressure is needed to get the diamond blade cutting, you are simply guiding it along while applying light pressure to create friction. If you press to hard, it’ll create excessive heat and start melting the glaze on the tile or get it sparking. Firstly, try cutting much slower and see if that stops the sparking/burning. Also be sure to keep the tile saw as straight as possible during a cut and avoid twisting it during a cut.

Secondly, it could be your diamond blade that is the culprit! What kind of diamond blade are you using? I dry cut 90% of the time and very rarely do I get sparking or burning and that is thanks to my diamond blade. If it begins to burn or spark, I replace it.

Are you using the Hitachi supplied blade? If so, I would recommend on changing it for an aftermarket blade that work much better and do not burn. You can even take your Hitachi CM4SB2 to your nearest tile store or similar and get one that they recommend. Seriously, any blade would be better than the supplied one for cutting porcelain tile. I personally believe it’s your blade that is causing the burning and not your technique, so I would address your diamond blade first but do take heed of my cutting advice as well.

I sincerely hope I have given you some help on how to proceed from here. It saddens me to hear you are having troubles with your Hitachi and not getting the results you expected. It’s prompting me to try create some beginner guides to hand-held tile saws as I bet they will help someone out in the future and hopefully avoid repeat cases of your problems.

Please let me know if you have other questions, I’ll do what I can to help.

Thanks for visiting and reading,

Carl.

Excellent job Carl. DIYER with one round cutout for bathroom sink in granite using hand grinder and edge beveler with plywood template. It took awhile. I added a spray nozzle to the variable speed grinder. Based on this experience, I decided to buy the Makita 4100KB and add a spray nozzle. I will also add some open cell foam over air vents and use a wet vac to reduce over spray. Also will be using a contour cutting blade. Live and learn, 3 more sinks to go.

Thanks again for sharing your invaluable experience. Very rare stuff. Archeologists can tell alot by looking at the bones and tools.

Carl this was the best in depth review I have ever read. I would love to read more of your reviews. I have had my own Handyman business for the past 6 years and always look for reviews before I buy any tool.

Hi John,

Thank you for the comment! I really appreciate it and I’m happy to hear you enjoyed my article.

You are more than welcome to read more of my reviews, I have a number of them kicking around on this website alongside my tiling tutorials. I’ll continue to review new power tools when I get my hands on them as well. Since all of these tools come from my own pocket, sadly I cannot write as many as I would like to!

Congrats on running your own business for so many years, I bet you have a wealth of knowledge yourself with all the different things you fix and build in your line of work.

Thanks for stopping by and leaving me a comment, it’s always nice to hear from my readers.

– Carl.

Is the Matabo the exact same saw only change of name ? And does anyone sell the complete water kit as a package ?

Thanks Ron

Hi Ron,

Thanks for dropping by my website and commenting.

Yes, that is correct! To quote their own marketing speak “Same tools. New name. Hitachi Power Tools has renamed to Metabo HPT”. Metabo was owned by Hitachi for years but recently a new investor came on board and shuffled the names around. In some markets Hitachi is now called Hikoki.

This is mainly due to a corporate reshuffle and similar nonsense that makes no sense but rest assured the CM4SB2 is the same quality tool, just carries a different badge.

I have done some digging around and unfortunately cannot find the wet cutting kit as a complete package. In essence, the most vital part is the water plug that fits onto the tile saw and the vinyl hose. The third component is the water pump or the hose attachment, you can choose whichever you prefer. I personally recommend a water pump.

Please let me know if you have any further questions, I’ve been using the CM4SB2 on a daily basis for years and happy to share my experience with it.

Thanks,

Carl.

Thanks for the info, I should be receiving it this week. I am doing a bathroom remodel & will be using it on some 16 x 32 porcelain tile for floor & shower !!

Ron

Just received the rubber connector Hitachi # 956-885 & it does not fit any hose I have, My little finger fits in the size of threads. what kind of garden hose has a thread to fit this ?? All US hose fit a normal spray nozzle, What am I not getting here ??

Ron

Hey Ron,

Try using a basic hose connector first, and then fit the water plug over it. I never understood that design concept either,

If that fails, try returning it and just using a submersible water pump. That way you don’t need to be close to a hose to set-up your cutting station.

Hope you get it all working soon!

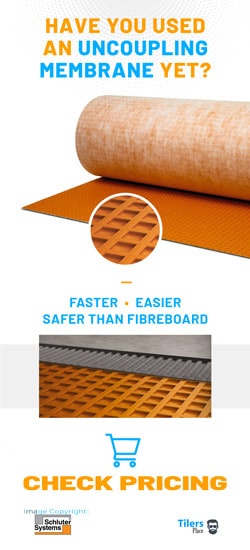

Machined a adapter to fit small hose & clamp into garden hose, All good now !! Have not used saw yet but just finished Schluter membrane in a 6×6 shower & getting ready to start laying tile.

Ron

Excellent work Ron!

I’m happy to hear you figured out a way to get your hose fitted properly. Sorry to hear you had to go out of your way and machine a part but it sounds like your ingenuity saved the day!

All the best with your shower project. It sounds like you are on the right track with the Schluter membrane.

Thanks for dropping in again!

Can I use A hand held saw in place of a table wet saw ?

Hi Colby,

You surely can, but it truly depends on what type of jobs you do most in your area.

I personally haven’t used a table saw for over 10 years as my hand held tile saw and Rubi tile cutters are all I need for my jobs. I very occasionally bust out my small table saw for fiddly mosaics.

If you work with mostly porcelain or ceramic tiles then you can easily do away with the table saw as a hand held tile saw can do all the tricky cuts and mitres that you need. The occasional natural stone jobs can be handled by the wet cutting ability of the hand held tile saws as well. IF you are working with lots of natural stone then it’d probably be better to get a large table saw.

Hope that helps.

I am a tiler install of more then 35 Years. I have owned or used almost every kind of diamond saw there is. My last main tile saw was the Sigma 10M class, with a whopping 3 Horse power motor.

Back in my 20s I used a 4 inch Makita 4200n plywood saw, with the blade guard pinned back, and a very basic turbo blade, lots of chipping. the 4200N is the 4100NH with a blade guard. Not much else has changed in over 30 years really.

Then I had a panel tile job that was coming up. I remembered that old Makita saw I once had, and start looking into updating things. The long and short. I know own 3 Metabo’s, thanks to this review. One for standard cuts, and one mounted to a custom made miter system. Both are used wet. The 3rd is in a box on standby, just in case.

Since I start using them, I haven’t found a reason to pull the big old beast of a table saw out. The poor thing just sits in the shed going rusty.

Once you get a nice Super Thin Turbo blade on these Metabo’s, and start using them, you find out just how flexible they are.

I could write many paragraphs about my experiences with these saws. But, I’m sure everyone got the message before they even made it down to the Forms.

Now for the Sad news.

https://www.metabo-hpt.com/us/main-navigation/item/cm4sb2-4-dry-cut-masonry-saw-Metabo-HPT

Metabo has decide to discontinue this amazing saw.

The Address above will take you to the Metabo page for this saw, and of coarse, the bad news.

So may want to buy one or two extras.

Happy Tiling Everyone.

Hi Paul,

Thank you for the valuable insight and sharing your story. You’re definitely a seasoned setter and my utmost respect goes out to you from one professional to another. I’m thrilled to hear you’ve found success with the CM4SB2. It’s great to hear the saw has worked well for you, it truly is a little beast.

I’m truly saddened by the news you’ve linked! I can’t believe they have pulled the plug on this amazing saw, I’ve been using them exclusively for over 10 years now and can’t imagine switching to a lesser saw. I can only hope they will be coming out with an updated model at some point.

Thank you for bringing this to my attention nonetheless, I have already purchased two extra units to keep myself stocked for the future and I hope others will read this. If you like the saw friends, buy an extra one!

Meanwhile, I’ll try contact Metabo and see if I can get an official answer as to why they are killing the CM4SB2.

Thanks for visiting Paul and sharing this intel with us, it’s truly appreciated.

Thank you Car

It nice to find those that share the same enthusiasm amongst so many that have interests else where.

Regarding your reaching out to Metabo. Please share your results with us here. I am still in self debate, on if I should acquire another saw for backup. Or, wait and find out if a replacement is in the works. But, the little voice inside me says they discontinued the saw, do to slow sales, and have no plans to replace it. Ceramic tile tools just don’t move like carpentry tools.

Until then.

Greetings from Vancouver Canada.

Cheers

Paul.

Hi Paul,

I share your sentiment. It’s rare to find an enthusiast of hand held tile saws, especially when most of our contemporaries in this field prefer angle grinders or table saws.

My little voice agrees with you there as ceramic tile tools really do seem to be a small priority these days. It shows on how rarely these saws get updated. The models available from Makita have been around for at least 20 years without any updates. It defies logic in my mind. The Makita 4101RH still uses a hose clamp to hold the end cap for pete’s sake. It looks like a home fixup job not a brand new tool.

I really do hope they are working on an updated model as I’d love a new Metabo saw but who knows.

I have contacted Metabo USA and am awaiting a reply. If I hear anything I’ll email you on the provided email – it’ll save you checking back here for any updates. I’ll also post an update here if anyone’s interested.

Take care,

Carl.

For anyone following this thread – Official Word From Metabo is the CM4SB2 is NOT being discontinued! I contacted them and they informed me it was a website error. Our favorite tile saw is still being made so we can continue cutting in peace.

Sorry,

Thank you Carl.

The L on Key Board is a hard press sometimes..